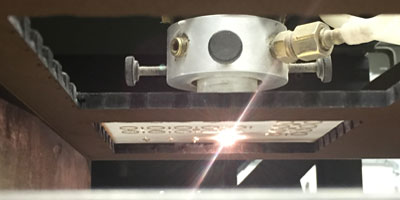

China Zirconia Ceramic Inc. modern, fully equipped facility allows us to meet the demands of our constantly changing industry. China Zirconia Ceramic Inc. laser department has the abilities to machine a variety of materials from ceramics to plastics and more. Our laser capabilities allow us to fulfill the demands of our high volume customers along with prototypes & R&D projects. Quality and competitive pricing are guaranteed. We are committed to providing our customers with quality parts and services. Our attention to customer needs made us a leader in our field. China Zirconia Ceramic Inc. has knowledge to direct you to the most effective and appropriate material for your specific application.

Laser Engraving Service

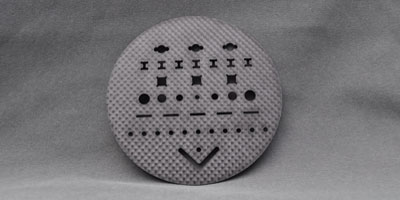

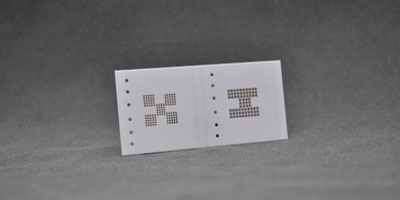

Laser Etching

Laser Marking Services

Ceramic Laser Machining

| Part # | Thickness | Length | Width |

|---|---|---|---|

| AS1-30 | 0.010" | 4½" | 4½" |

| AS1-35 | 0.015" | 4½" | 4½" |

| AS1-40 | 0.020" |

4½" | 4½" |

| AS1-45 | 0.025" | 4½" | 4½" |

| AS1-50 | 0.030" | 4½" | 4½" |

| AS1-55 | 0.035" | 4½" | 4½" |

| AS1-75 | 0.040" | 4½" | 4½" |

| AS1-80 | 0.050" | 4½" | 4½" |

| AS1-85 | 0.060" | 4½" | 4½" |

Alumina Substrates are engineered to minimize as-fired resistor variations and maximize aged adhension values. Superior resistor stability is achieved by controlling the substrates effects on the temperature coefficient of resistance. Alumina Substrates are particularly well suited for small geometry, high resistor value circuitry.

Standard Length & Width Tolerances: ± 1% NLT ± 0.004" (± 0.102MM)

Standard Thickness Tolerances: ± 10% NTL ± 0.002" (± 0.0508mm)

Standard Camber Tolerances: ≤ 0.003 in./in. (≤ 0.002 mm/mm)

If you would like to send us a drawing to quote, we have the capability to read most CAD formats. If you do not see the file extension you would like to send please contact us.